Entry number:08

SUBJECT

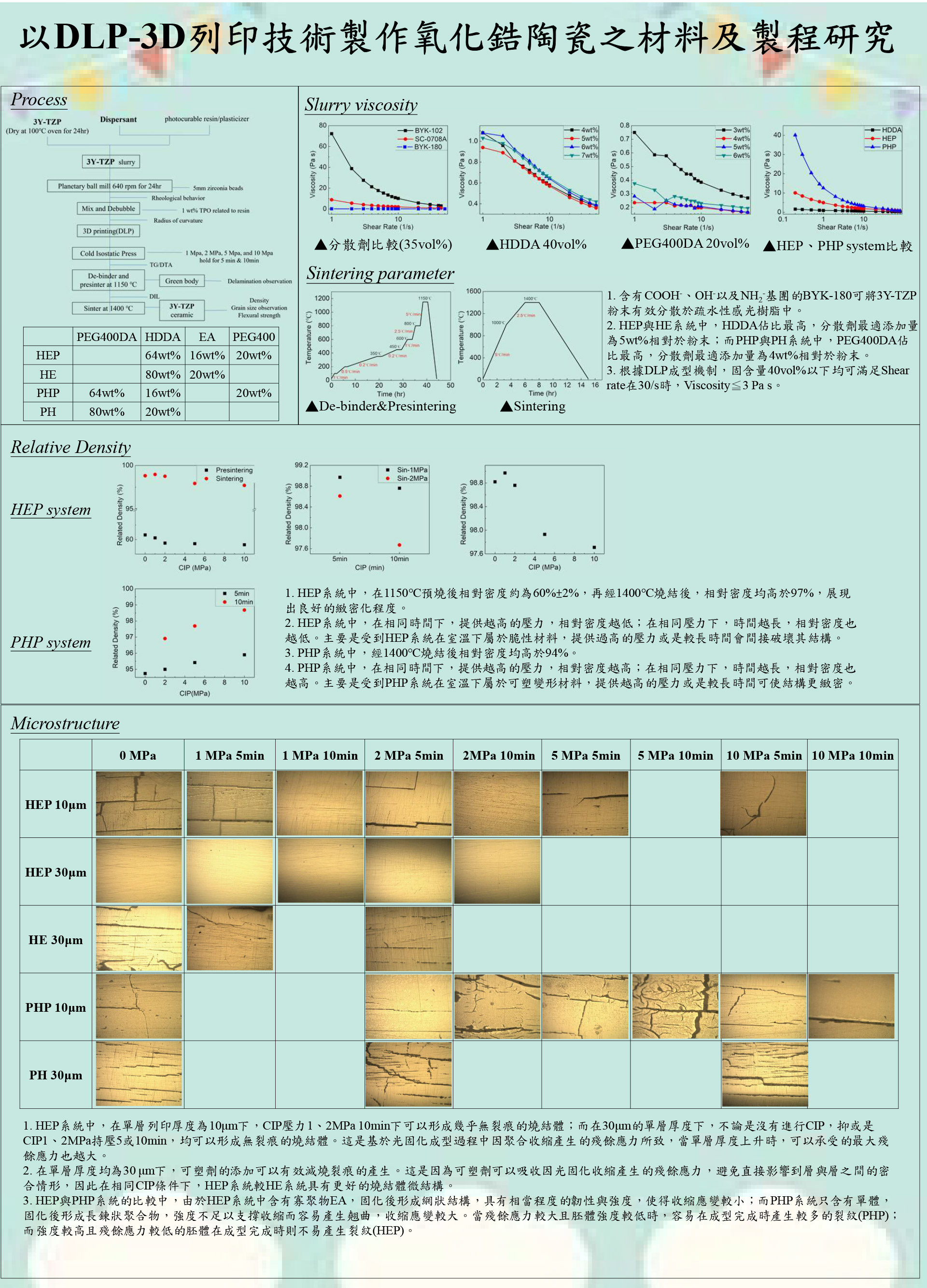

Research of material and process about zirconia ceramic through DLP-3D printing techniques

DEPARTMENT

Department of Resources Engineering

PROFESSOR AND STUDENT

Professor:Hsing-I Hsiang

Student:YEN JHEN YU

ABSTRACT

Zirconia ceramics have lots of mechanical properties including high mechanical strength, toughness and hardness, which are applied to industry like ceramic substrate, dental ceramics and solid electrolyte material. Digital light Process Stereolithography is a kind of polymer forming technique. This method is simple and cheap. The raw material is liquid or photosensitive resin, which will cause polymerization to happen if it is exposed to specific light source. Therefore, through controlling the region where light sources are, it can make different kinds of sample. If combining both zirconia ceramic powder and photosensitive resin on DLP techniques, it can make lots of ceramic appliance with complex shape as well as without any additional process and can maintain its good mechanical properties after sintering. In this study successfully produce the slurry which is suitable to DLP technique’s limit. Nano zirconia powder is used to make slurry with 40 vol% solid content in order to discuss how two different photosensitive resin system and different cold isostatic pressure(CIP) data affect the samples’ microstructure.Research indicates that CIP can effectively reduce the delamination. The system including oligomer only acquires 1MPa CIP pressure to improve delamination due to its high glass transition temperature and brittle properties. Its relative density can reach to 98.97%. In the other hand, the system including only monomer acquires 10MPa CIP pressure to improve delamination due to its low glass transition temperature and elastic properties. Its relative density can reach to 98.68%.

Sweepstake

Sweepstake